The German firm will use the investment to further expand its German wafer fabs in Dresden and Reutlingen and its semiconductor operations in Penang

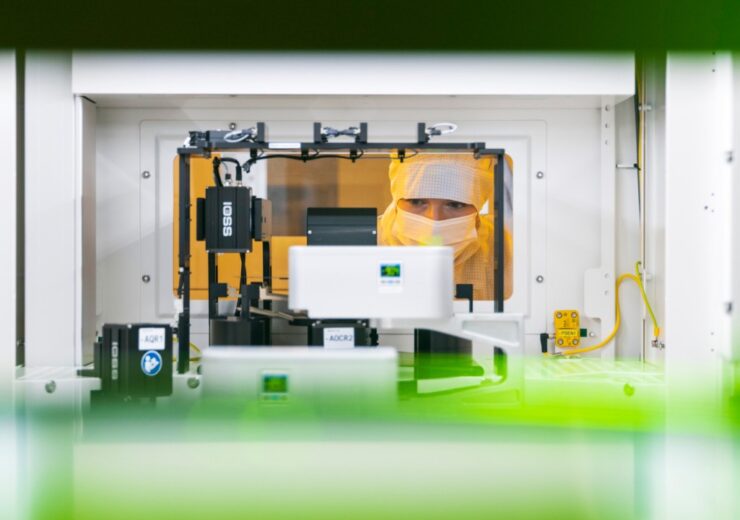

Bosch earmarks €400m investment in semiconductor fabs in 2022. (Credit: Robert Bosch GmbH)

Robert Bosch said that it intends to invest an additional amount of over €400m in 2022 in its chip manufacturing facilities (fabs) in order to address the global chip shortage.

The German engineering and technology company will use the investment to expand its wafer fabs in Dresden and Reutlingen in Germany as well as in its semiconductor operations in Penang, Malaysia.

Bosch board of management chairman Volkmar Denner said: “Demand for chips is continuing to grow at breakneck speed. In light of current developments, we are systematically expanding our semiconductor production so we can provide our customers with the best possible support.”

The wafer fab in Dresden was opened by the company in July 2021. The 300mm fab will get most of the announced investment to expand its manufacturing capacity even faster in 2022.

Bosch will invest nearly €50m in 2022 in the Reutlingen wafer fab near Stuttgart. The company has been manufacturing semiconductors at the Reutlingen fab since 1971.

The fab will see a total investment of €150m from 2021 to 2023 to create additional clean-room space.

The German company will add over 4,000m2 to the present clean-room space of 35,000m2 at the Reutlingen wafer fab in two phases.

Bosch board of management member Robert Bosch said: “Our aim is to ramp up production of chips in Dresden earlier than planned and at the same time expand clean-room capacity in Reutlingen. Every additional chip we produce will help in the current situation.”

In Penang, Bosch will construct a test centre for computer chips from scratch. The company aims to test finished semiconductor chips and sensors at the Malaysian automated and connected facility from 2023 onwards.

The company said that the additional testing capacity in Penang could give the opportunity of locating new technologies in its wafer fabs in the future. As an example, the company said that this could enable it to manufacture silicon carbide semiconductors at the Reutlingen fab.

Additionally, the company believes that the new location in Asia will reduce delivery times and distances for the semiconductors.