The company will build a new battery assembly plant, introduce mega casting of aluminium body parts, and fully refurbish paint and final assembly shops

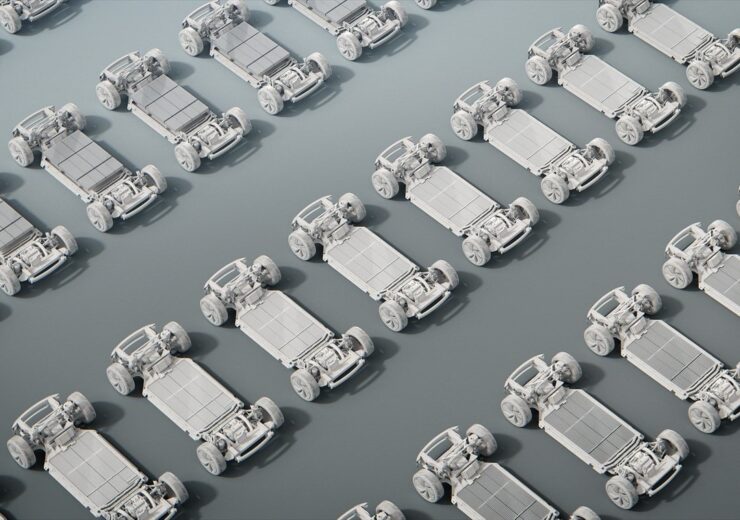

Illustration of the Torslanda battery assembly plant of Volvo Cars. (Credit: Volvo Car Group)

Volvo Cars revealed plans to invest SEK10bn ($1.1bn) in its Torslanda manufacturing plant in Sweden over the coming years in preparation for the production of next-generation fully electric cars.

The Swedish luxury car manufacturer said that it will use the investment to bring in a number of new and more sustainable technologies and manufacturing processes in the Torslanda plant.

Some of the plans include building a new battery assembly plant, introducing mega casting of aluminium body parts, as well as fully refurbishing paint and final assembly shops.

According to Volvo Cars, using a mega casting of aluminium body parts for the next generation of electric Volvo models is the most notable change to be brought in as part of the investment package.

The automobile firm said that mega casting will lead to various benefits in terms of cost, sustainability, and car performance during the vehicles’ lifetime.

Volvo Cars further stated that casting major parts of the floor structure of the vehicle as one single aluminium part cuts down weight, thereby boosting the energy efficiency and increasing the car’s electric range.

Besides, the approach is said to enable the company’s designers to use the available space inside the cabin and luggage area optimally in order to increase the overall versatility of the vehicle.

Volvo Cars’ new battery assembly facility in Torslanda is planned to integrate battery cells and modules in the floor structure of the car.

The company’s investment in Torslanda follows the recent announcement of constructing a SEK30bn ($3.3bn) battery manufacturing plant in Gothenburg, Sweden, in partnership with Northvolt.

Volvo Cars chief executive Håkan Samuelsson said: “With these investments, we take an important step towards our all-electric future and prepare for even more advanced and better electric Volvos.

“Torslanda is our largest plant and will play a crucial role in our ongoing transformation as we move towards becoming a pure electric car maker by 2030.”

Opened in 1964, the Torslanda manufacturing plant can produce 300,000 cars per year.