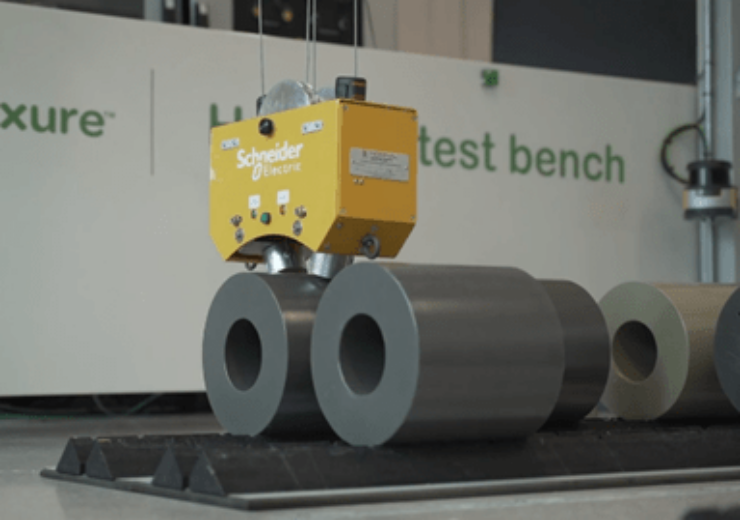

The three companies will collaborate to design and deploy the 5G-enabled automated hoisting solution at Schneider Electric’s hoisting lab in Grenoble, France

Schneider Electric joins forces with Capgemini and Qualcomm to speed up 5G industrial automation. (Credit: Schneider Electric)

France-based Schneider Electric has joined forces with technology firms Capgemini and Qualcomm to expedite 5G industrial automation.

The three companies will collaborate to design and deploy a 5G-enabled automated hoisting solution at Schneider Electric’s hoisting lab in Grenoble, France.

By replacing wired connections with wireless and integrating existing wireless connections from the French firm’s industrial automation system, the solution will streamline digital technology deployment at scale across industrial sites from steel plants to ports.

According to Qualcomm, automated hoisting systems enhance productivity, safety, and operation performance, but they need fast reaction time, high accuracy, round-the-clock availability, and both manual and autonomous capabilities.

Besides, several systems must be on the same network with video cameras for monitoring and remote operation, as well as programmable logic controllers (PLCs) for various control functions such as automation, remote control, and safety functions.

With 5G’s native low latency characteristics, the system is enabled to replace fibre cables in remote-control operations which will simplify network complexity, reduce wires, and ensure long-term reliable connectivity, said Qualcomm.

The private 5G automated hoisting system can now be utilised to offer new digital use cases, including augmented operators enabled by eXtended Reality (XR) and wearable devices.

Schneider Electric innovation and upstream marketing vice president Marc Lafont said: “This breakthrough end-to-end 5G private network hoisting solution is a perfect example of the power of working together as we pilot it at end user sites this year.

“In addition, in the short-term, we will validate more industrial 5G use cases in various discrete manufacturing, hybrid automation, and process automation applications. In the mid-term, we will experiment with deeper integration of 5G technology inside our automation equipment.”